본문

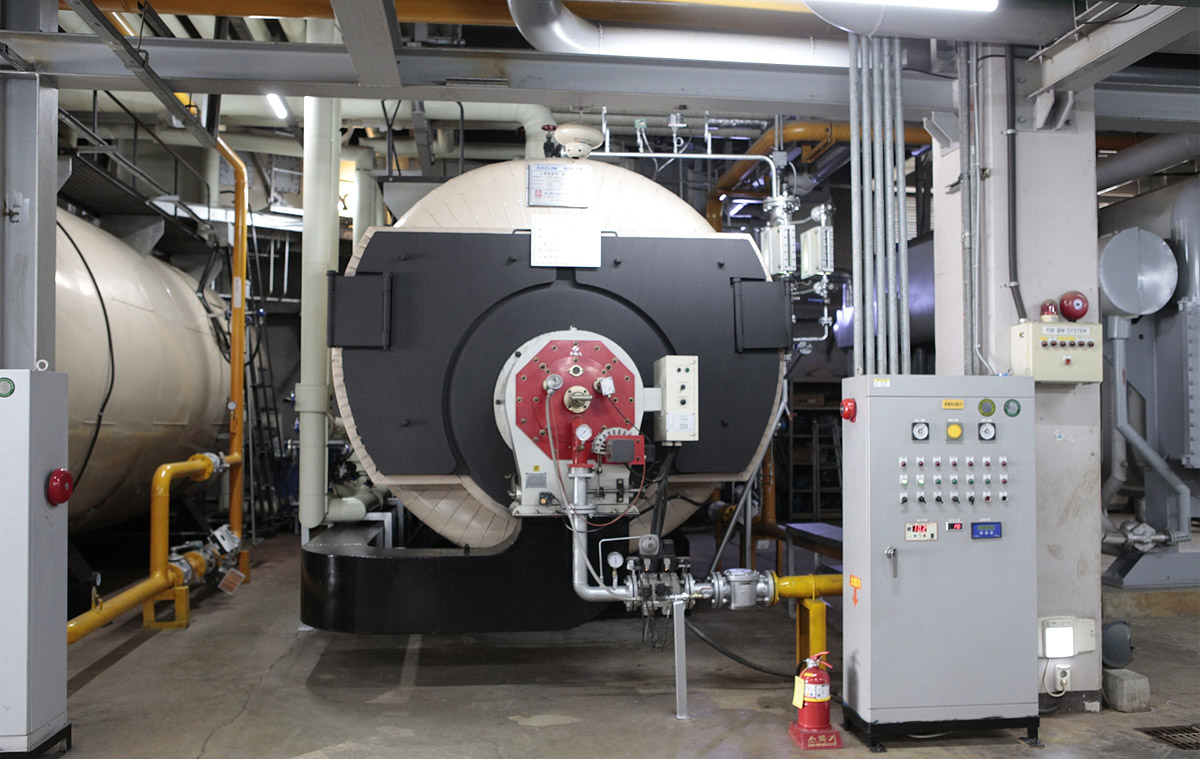

Smoke Tube Package Boiler

From Small-Scale (1T/H) to Large-Scale (15T/H)

Reliable Fire Tube Boilers for Steam and Hot Water Applications

Reliable Fire Tube Boilers for Steam and Hot Water Applications

Daelim’s fire tube boilers, designed to run on oil or gas, cater to diverse needs such as steam production, hot water supply, and heating for production facilities and other uses.

The DL-A model fire tube boiler, with a capacity of up to 15 tons, is built simply yet robustly using steel pipes and tubes. This design makes it convenient for industrial steam generation, hot water supply, and heating, serving as a key driving force for domestic industries. Recognized for their high performance, these boilers use oil and gas as fuel and have proven their value across various industries.

Innovative Design and High Efficiency The DL-A model has been refined through technological advancements to better meet industrial demands. By optimizing the combustion chamber for flame propagation and ensuring adaptability to load fluctuations, these boilers achieve an ideal balance of efficiency, safety, and reliability.

Compact and Easy Installation One of the standout advantages of the fire tube boiler is its ability to be installed as a complete unit in compact spaces, significantly reducing installation time.

Global Recognition and Exports Thanks to consistent research and development, Daelim boilers boast enhanced safety and automation, which have made them popular in international markets.

The DL-A model fire tube boiler, with a capacity of up to 15 tons, is built simply yet robustly using steel pipes and tubes. This design makes it convenient for industrial steam generation, hot water supply, and heating, serving as a key driving force for domestic industries. Recognized for their high performance, these boilers use oil and gas as fuel and have proven their value across various industries.

Innovative Design and High Efficiency The DL-A model has been refined through technological advancements to better meet industrial demands. By optimizing the combustion chamber for flame propagation and ensuring adaptability to load fluctuations, these boilers achieve an ideal balance of efficiency, safety, and reliability.

Compact and Easy Installation One of the standout advantages of the fire tube boiler is its ability to be installed as a complete unit in compact spaces, significantly reducing installation time.

Global Recognition and Exports Thanks to consistent research and development, Daelim boilers boast enhanced safety and automation, which have made them popular in international markets.

Features and Benefits

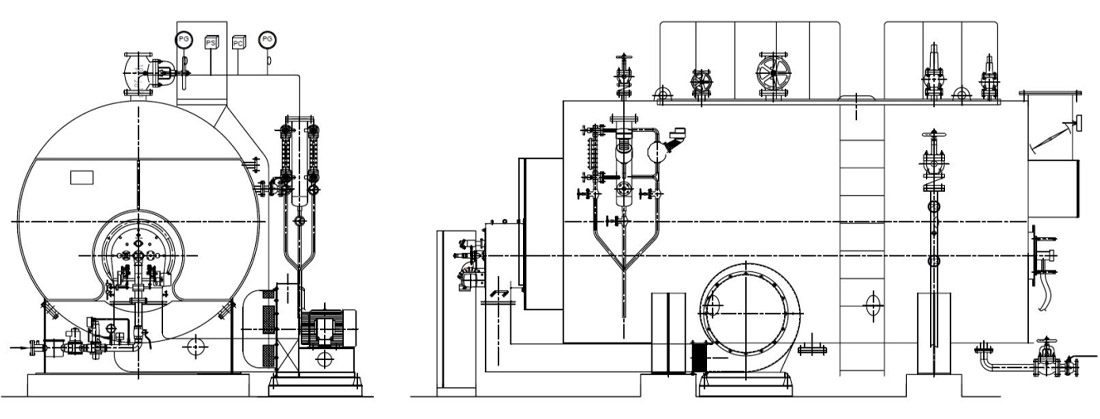

Rational Structure

The 3-pass structure allows smooth regulation of water circulation by directing the flow of combustion gases, making it compatible with various burners.

Lightweight and Compact Design

For convenient transport and installation, even mid-capacity models are offered as packaged units.

Superior Safety

Equipped with reliable safety devices for pressure and flame monitoring, ensuring stable and secure operation

Easy Maintenance

The boiler’s design makes external inspections and cleaning of tubes straightforward and hassle-free.

Structural Features

Specifications

Drag screen right and left

Drag screen right and left| ItemsModel | DL-A-10 | DL-A-15 | DL-A-20 | DL-A-25 | DL-A-30 | DL-A-35 | DL-A-40 | DL-A-45 | DL-A-50 | DL-A-60 | DL-A-70 | DL-A-80 | DL-A-100 | DL-A-120 | DL-A-150 | |

| Main Body | Rated evaporation amount kg/h |

1000 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 5000 | 6000 | 7000 | 8000 | 10000 | 12000 | 15000 |

| Max. operating pressure Mpa(kg/㎠) |

1.0(10) | |||||||||||||||

| Total calories generated kcal/h |

603,700 | 905,550 | 1,207,400 | 1,509,250 | 1,811,100 | 2,112,950 | 2,414,800 | 2,716,650 | 3,018,500 | 3,622,200 | 4,225,900 | 4,829,600 | 6,037,000 | 7,244,400 | 9,055,500 | |

| Mw | 0.70 | 1.1 | 1.4 | 1.8 | 2.1 | 2.5 | 2.8 | 3.2 | 3.5 | 4.2 | 4.9 | 5.6 | 7.0 | 8.4 | 10.5 | |

| Efficiency % |

90 | |||||||||||||||

| Heat transfer area ㎡ |

23 | 39 | 49 | 56 | 63 | 78 | 84 | 93 | 104 | 130 | 134 | 158 | 210 | 239 | 291 | |

| Weight kg |

5000 | 6300 | 7500 | 8200 | 8500 | 9700 | 11400 | 12600 | 13800 | 17400 | 17500 | 19200 | 24900 | 29000 | 31900 | |

| Water reserves(when full) kg |

2500 | 4300 | 5600 | 5900 | 6600 | 7400 | 7700 | 9300 | 10100 | 13300 | 13300 | 15000 | 19100 | 21700 | 22900 | |

| Fuel consumption | LNG(9550) N㎥/hr |

70 | 105 | 140 | 176 | 211 | 546 | 281 | 316 | 351 | 421 | 492 | 562 | 702 | 843 | 1054 |

| LPG(13800) N㎥/hr |

49 | 73 | 97 | 122 | 146 | 170 | 194 | 219 | 243 | 292 | 340 | 389 | 486 | 583 | 729 | |

| Diesel(10300) kg/h |

65 | 98 | 130 | 163 | 185 | 228 | 260 | 293 | 326 | 391 | 456 | 521 | 651 | 781 | 977 | |

| Bunker C oil(9750) kg/h |

69 | 103 | 138 | 172 | 206 | 241 | 275 | 310 | 344 | 413 | 482 | 550 | 688 | 826 | 1032 | |

| Connection diameter | Steam outlet A | 65 | 80 | 80 | 80 | 100 | 100 | 100 | 125 | 125 | 125 | 150 | 150 | 200 | 200 | 200 |

| Water supply inlet A | 40 | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Auxiliary valve A | 40 | 40 | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Water gauge A | 40 | |||||||||||||||

| Waterspout A | 50 | |||||||||||||||

| Safety valve A | 25 | 40 | 40 | 25/40 | 25/40 | 25/40 | 25/40 | 40/40 | 25/50 | 40/40 | 40/40 | 40/50 | 40/65 | 50/65 | 50/80 | |

| Smoke outlet ㎜ | 240x280 | 26x380 | 320x430 | 350x450 | 370x530 | 380x580 | 430x610 | 430x650 | 520x610 | 520x750 | 650x830 | 550x830 | 550x950 | 600x1100 | 700x1100 | |

| Manhole ㎜ | 280x380 | |||||||||||||||

| External size (excluding insulation) |

Width ㎜ | 1500 | 1700 | 1800 | 1950 | 1850 | 2000 | 2000 | 2150 | 2250 | 2350 | 2600 | 2650 | 2800 | 3000 | 3000 |

| Height ㎜ | 1950 | 2100 | 2250 | 2200 | 2300 | 2400 | 2450 | 2600 | 2700 | 2800 | 3100 | 3100 | 3250 | 3450 | 3500 | |

| Length ㎜ | 3900 | 3600 | 4200 | 4000 | 4550 | 4650 | 5000 | 5000 | 5200 | 5200 | 5500 | 5600 | 6550 | 6700 | 7020 | |

- The above specifications were created based on the following.

- Steam pressure: 1.0 (Mpa), steam enthalpy: 663.7 (kcal/kg), water supply temperature: 60 (℃), gas supply pressure: medium pressure (2000~4000mmAq)

- Fuel low calorific value: natural gas (LNG) 9550 (kcal/Nm2), city gas (LPG) 13800 (kcal/Nm2), Diesel 10300, B-C 9750 (kcal/kg)

- The above boiler specifications are subject to change without notice for quality improvement.