본문

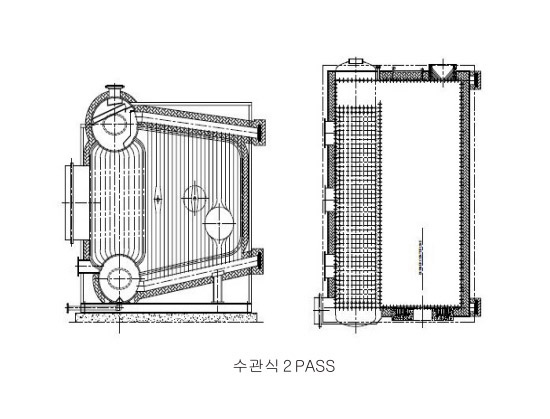

Water Tube Package Boiler

Daelim Water Tube Boilers

Unmatched Efficiency,

Safety,

Durability

Unmatched Efficiency,

Safety,

Durability

Daelim's water tube boilers are widely used for medium to large-scale applications, including power generation. Backed by dedicated research and development, they offer the following outstanding advantages:

The DL-P model water tube boiler, equipped with numerous non-heated steel tubes, is designed to deliver superior steam generation performance while ensuring fuel savings and safety. Built with a focus on the unique needs of each production facility, it accommodates various specifications for capacity, pressure, temperature, and fuel type, thanks to the expertise of Daelim's engineering team.

The DL-P model water tube boiler, equipped with numerous non-heated steel tubes, is designed to deliver superior steam generation performance while ensuring fuel savings and safety. Built with a focus on the unique needs of each production facility, it accommodates various specifications for capacity, pressure, temperature, and fuel type, thanks to the expertise of Daelim's engineering team.

Features and Benefits

Unmatched Efficiency

Daelim’s water tube boilers are designed and manufactured with an optimized structure that suits the fuel and application requirements of every client.

Superior Safety

Equipped with advanced safety features such as pressure monitoring, flame detection, automatic fuel adjustment, and water supply regulation, these boilers guarantee safe and reliable operation.

Exceptional Durability

The robust design and manufacturing techniques ensure the highest durability, offering a long service life and consistent performance with minimal downtime.

Structural Features

- The boiler is designed with water-cooled walls for all outer surfaces, including the front and rear of the combustion chamber, as well as the baffle wall dividing the furnace from the water tube section. This minimizes heat loss and enhances efficiency.

- An ideal arrangement of water tubes ensures stable water levels while maintaining excellent water circulation.

- Separate non-heated steel tubes are placed for optimal circulation, ensuring exceptional heat transfer, extended tube life, and consistent operation at pressures above atmospheric conditions.

- The completely sealed exterior prevents heat leaks, making this boiler a reliable solution for industrial use.

Standard Specifications

Drag screen right and left

Drag screen right and left| ItemsModel | DL-P-20 | DL-P-30 | DL-P-40 | DL-P-50 | DL-P-60 | DL-P-70 | DL-P-80 | DL-P-100 | DL-P-120 | DL-P-150 | DL-P-200 | DL-P-250 | DL-P-300 | DL-P-400 | |

| Main Body | Rated evaporation amount kg/h |

2000 | 3000 | 4000 | 5000 | 6000 | 7000 | 8000 | 10000 | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 |

| GAS flow PASS |

3 | 2 | |||||||||||||

| Max. operating pressure Mpa(kg/㎠) |

1.0(10) | ||||||||||||||

| Total calories generated kcal/h |

1207400 | 1811100 | 2414800 | 3018500 | 3622200 | 4225900 | 4829600 | 6037000 | 7244400 | 9055500 | 12074000 | 15092500 | 18111000 | 24148000 | |

| Mw | 1.40 | 2.1 | 2.8 | 3.5 | 4.2 | 4.9 | 5.6 | 7.0 | 8.4 | 10.5 | 14.0 | 17.6 | 21.1 | 28.1 | |

| Efficiency % |

90 | ||||||||||||||

| Heat transfer area ㎡ |

54 | 81 | 92 | 106 | 155 | 167 | 175 | 203 | 285 | 296 | .76 | 167 | 5.2 | 666 | |

| Weight kg |

5300 | 8000 | 8700 | 9000 | 11300 | 11600 | 12200 | 16200 | 24700 | 21200 | 24800 | 29400 | 34500 | 41700 | |

| Water reserves(when full) kg |

3000 | 4700 | 5000 | 5200 | 6300 | 6700 | 6900 | 7800 | 13600 | 11200 | 15000 | 15900 | 17400 | 23000 | |

| Fuel consumption | LNG(9550) N㎥/hr |

140 | 211 | 281 | 351 | 421 | 492 | 562 | 702 | 843 | 1054 | 1405 | 1756 | 2107 | 2810 |

| LPG+AIR(13800) N㎥/hr |

97 | 146 | 194 | 243 | 292 | 340 | 389 | 486 | 583 | 729 | 972 | 1215 | 1458 | 1944 | |

| Diesel(10300) kg/h |

130 | 195 | 560 | 326 | 391 | 456 | 521 | 651 | 781 | 977 | 1302 | 1628 | 1954 | 2605 | |

| Bunker C oil(9750) kg/h |

138 | 206 | 275 | 344 | 413 | 482 | 550 | 688 | 826 | 1032 | 1376 | 1720 | 2064 | 2752 | |

| Connection diameter | Steam outlet A | 80 | 100 | 100 | 125 | 125 | 150 | 150 | 200 | 200 | 200 | 200 | 250 | 300 | 300 |

| Water supply inlet A | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 65 | 65 | 65 | 80 | 80 | |

| Auxiliary valve A | 40 | 40 | 40 | 40 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 80 | |

| Water gauge A | 40 x 2EA | ||||||||||||||

| Waterspout A | 50 | ||||||||||||||

| Safety valve A | 25/25 | 25/40 | 25/40 | 40/40 | 40/50 | 40/50 | 50/65 | 50/65 | 50/65 | 50/65 | 80/80 | 65/100 | 80/100 | 80/125 | |

| Smoke outlet ㎜ | 250x600 | 435x500 | 435x600 | 510x850 | 510x1000 | 510x1050 | 510x1200 | 510x1200 | 600x1400 | 600x1400 | 600x1400 | 600x1600 | 900x1800 | 900x1800 | |

| Manhole ㎜ | 280x380 | ||||||||||||||

| External size (excluding insulation) |

width ㎜ | 2200 | 2700 | 2800 | 3050 | 3050 | 3200 | 3150 | 3350 | 4050 | 3850 | 3850 | 4050 | 4450 | 5050 |

| Height ㎜ | 2700 | 2850 | 3200 | 3000 | 3500 | 3600 | 3600 | 3700 | 4350 | 3900 | 4700 | 4900 | 4900 | 5700 | |

| length ㎜ | 2800 | 3505 | 3100 | 3100 | 3650 | 3900 | 3900 | 4800 | 5600 | 5600 | 5600 | 5650 | 5950 | 6600 | |

- The above specifications were created based on the following.

- Steam pressure: 1.0 (Mpa), steam enthalpy: 663.7 (kcal/kg), water supply temperature: 60 (℃), gas supply pressure: medium pressure (2000~4000mmAq)

- Fuel low calorific value: natural gas (LNG) 9550 (kcal/Nm2), city gas (LPG+Air) 10300 (kcal/Nm2), B-C 9750 (kcal/kg)

- The above boiler specifications are subject to change without notice for quality improvement.